Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

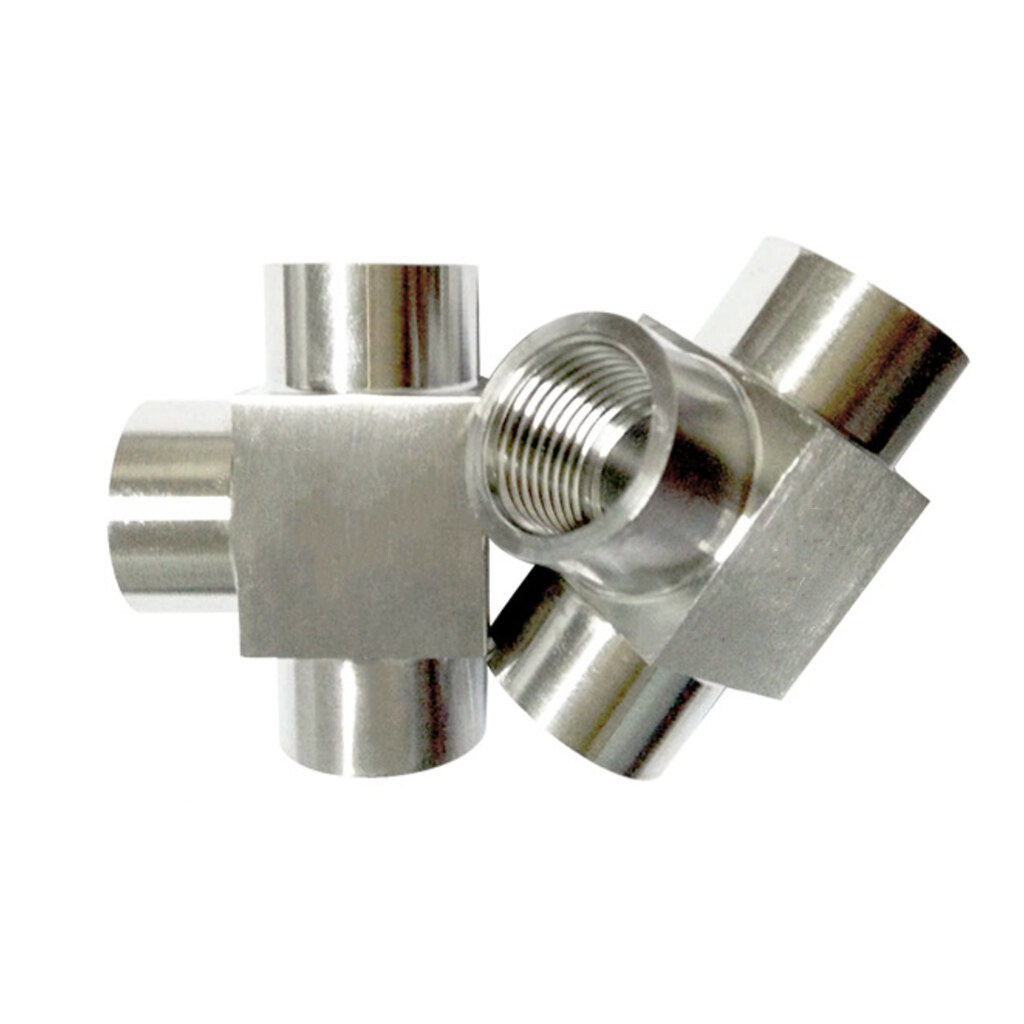

Stainless Steel Connector Fittings Compression Tube Fittings Double Ferrule Fittings

The joint body, ferrule, and nut make up the stainless steel double ferrule joint. When the nut is tightened after the ferrule and nut sleeve have been inserted into the joint body of the steel pipe, the inner blade of the ferrule evenly bites into the seamless steel pipe to create an effective seal. The ferrule's outer surface fits the joint body's conical surface. Corrosion resistance, high pressure resistance, ease of installation, and longevity are all properties of the ferrule joint.

Stainless Steel Connector Fittings Compression Tube Fittings Double Ferrule Fittings

The stainless steel double ferrule joint consists of three parts: joint body, ferrule and nut. When the ferrule and the nut sleeve are inserted into the joint body on the steel pipe, and when the nut is tightened, the outside of the front end of the ferrule fits the conical surface of the joint body, and the inner blade evenly bites into the seamless steel pipe to form an effective seal. The ferrule joint has the characteristics of corrosion resistance, high pressure resistance, simple installation and durability.

The working principle of Stainless Steel Connector Fittings Compression Tube Fittings Double Ferrule Fittings

The steel pipe is inserted into the ferrule, secured with the ferrule nut, touched to the ferrule, cut into the pipe, and sealed therein according to the ferrule joint's working principle. When it is connected to the steel pipe, it does not need to be welded, which is advantageous for high-altitude operation, fire prevention, and explosion prevention. It can also eliminate the drawbacks brought on by accidental welding.

The installation of Stainless Steel Connector Fittings Compression Tube Fittings Double Ferrule Fittings

1. Saw off the seamless steel pipe of appropriate length and remove the burr at the port. The end face of the pipe shall be perpendicular to the axis, and the angle tolerance shall not be greater than 0.5°.

2. Put the nut and ferrule on the seamless steel pipe. Pay attention to the direction of the nut and ferrule, do not install it backwards.

3. Apply lubricating oil to the pre-assembled joint body thread and ferrule, insert the pipe into the joint body, and tighten the nut by hand.

4. Tighten the nut until the ferrule catches the tube. This turning point can be felt by increasing the tightening torque.

5. After reaching the pressure point, tighten the compression nut by 1/2 turn.

6. Remove the pre-assembled joint body and check the embedding of the edge of the ferrule. The visible protruding band must fill the space on the end face of the ferrule. The ferrule can be rotated slightly, but cannot be pushed axially.

7. For the final installation, apply lubricating oil to the thread of the joint body in the actual installation, and tighten the compression nut to cooperate with it until the tightening force can be felt. Then tighten 1/2 turn to complete the installation.